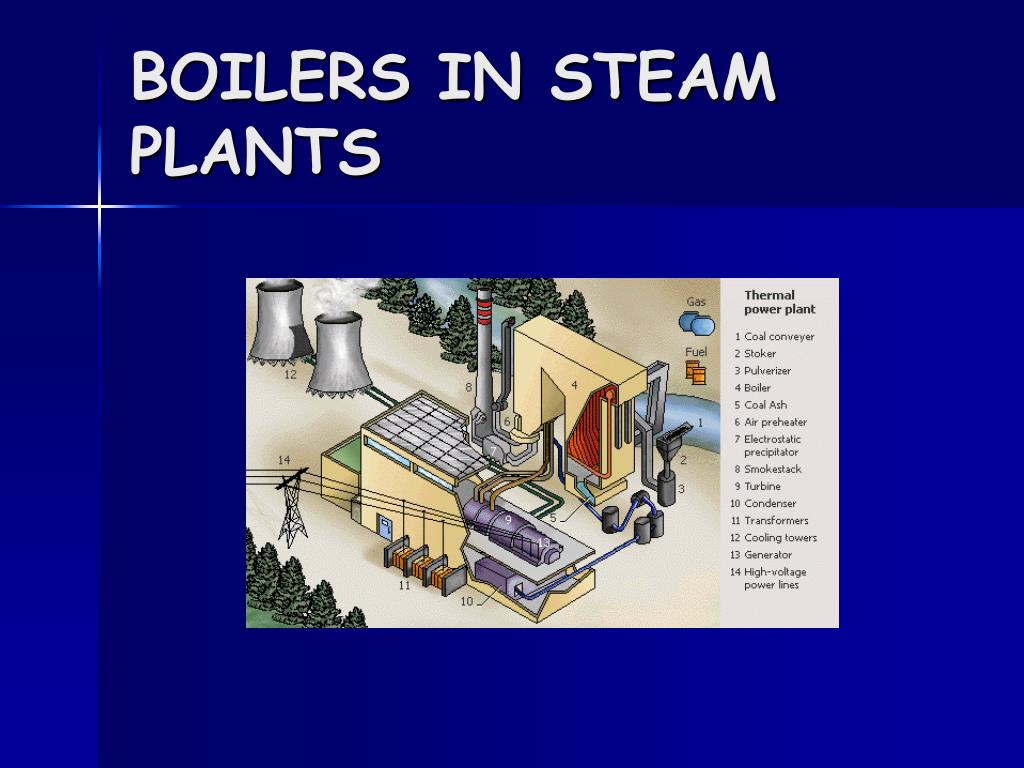

The so-called fire-tube boiler is a gas produced by combustion of fuel in the fire extinguishers or smoke too Header Pipe, fire extinguishers or smoke on the external water pipes, vapor or steam mixture is heated. ⑦ by the use of the boiler is divided into: life, boilers, industrial boilers, power station boilers and hot water boilers. ⑥ Press the tube through the water or gas can be divided into categories: fire-tube boilers, water boilers and fire tube boiler combined. ⑤ classified by the steam pressure can be divided into: low-pressure boilers, pressure in the boiler, high-pressure boiler, high pressure boiler, high pressure boilers, sub-critical pressure boilers and supercritical pressure boiler. ④ can be divided into categories according to whether the drum: the drum boiler and the boiler. ③ Classification by way of the boiler water circulation can be divided into: natural circulation boilers, forced circulation boilers and combined cycle boilers. ② Classification by combustion can be divided into: layer burning furnace, burning furnace room and in between the boiling (fluidized bed) boiler. ① fuel burned by the boiler can be divided into categories: coal-fired furnaces, oil heaters and gas furnaces.

#BABCOCK AND WILCOX BOILER PPT HOW TO#

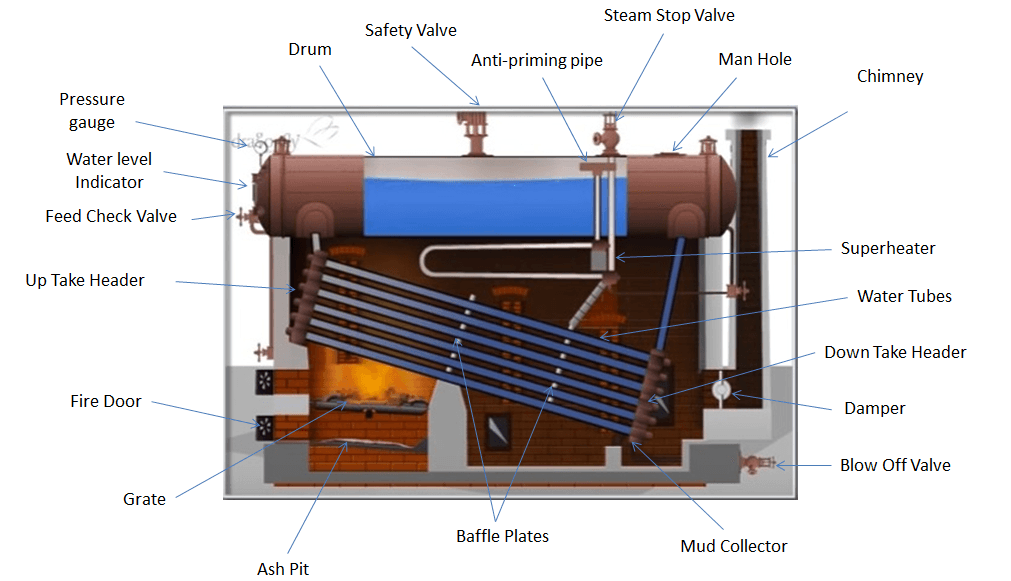

2.the boiler how to classify Boiler can be classified in different ways: For example, both the air preheater heat-absorbing part, the part is heat, either as part of the pot can also be seen as part of the furnace. Unlike most modern boilers and furnaces household use as distinguish pot. can be seen as part of endothermic pot the furnace, burners, fuel pump, delivery, suction fan can be seen as furnace. For example, water wall, superheater, economizer, etc. Capacities will vary depending on conditions and limitations.The other heat energy into the other working fluids, production parameters and quality of provision of equipment known as the boiler working fluid.Boiler equipment, heat-absorbing part is called pot, heat the part called the furnace.

* Steam capacities shown are saturated steam. Because of B&W’s constant effort to improve design, equipment supplied may differ slightly from that described above. All package boilers are of membrane construction.Ģ. Operational flexibility – high turndown and fast load rampingġ.Sootblowers – for effective cleaning of the superheater, generating bank and other heat transfer surfaces Inverted loop, fully drainable superheaters – saves time during startup while minimizing the chances of over-heat during the pressure-raising stage.

#BABCOCK AND WILCOX BOILER PPT OFFLINE#

Water wash troughs and drains – facilitates offline water-washing Solid membraned division wall – prohibits furnace gases from bypassing generating tubes Grooved tube seats – protect against leaks during transportation and throughout operation apart) – contributes to a faster load response and helps prevent membrane thermal cracking Outer lagging – galvanized, weather-tight for outdoor installationsĭrum internals – ensure positive circulation, low moisture, high steam purity Rugged steel-based frame – supports boiler and allows jacking and skidding Gas-tight setting membrane – inhibits dew-point sulfur corrosion and outages caused by gas leaks Coen burners are installed in more than 15,000 plants worldwide and are engineered for optimized steam production and emissions control.įurnace wall water cooling – eliminates refractory and related maintenance They offer reliable power with low emissions, low auxiliary power requirements, simple operation, low maintenance and can be tailored for a variety of fuel options, including natural gas. They are engineered to meet unique capacity, space, fuel, emissions, transportation, installation and other requirements.

Through an agreement with John Zink Hamworthy Combustion (JZHC), B&W offers a comprehensive steam generation solution that pairs JZHC’s Coen® burners with B&W’s water-tube package boilers for refining, petrochemical, pulp and paper, mining, manufacturing, utilities and other industries.

0 kommentar(er)

0 kommentar(er)